Automatic analysis system for Ferrite volume measurement based on ASTM E562-05

Other applications

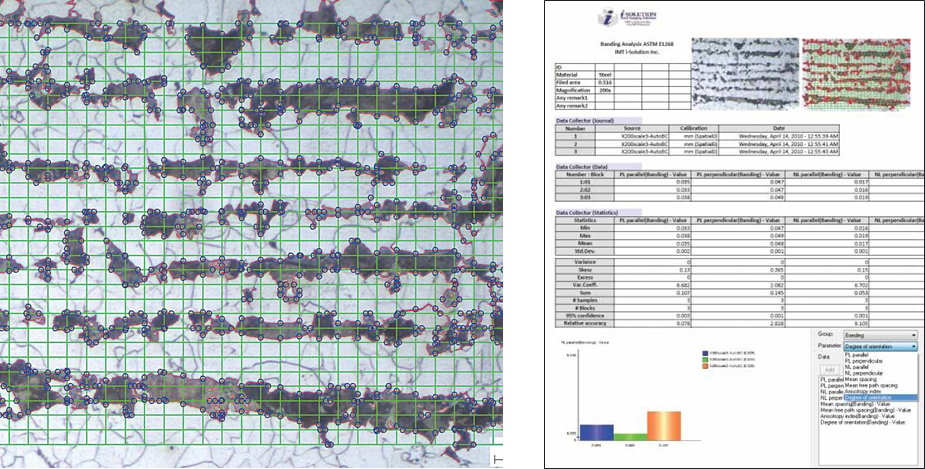

Assessing the Degree of Banding or Orientation of Microstructures by ASTM E 1268

- ASTM1268 Banding Analysis Assessing the Degree of Banding or Orientation of Microstructures by ASTM E 1268 Segregation occurs during the dendritic solidification of metals and alloys and is aligned by subsequent deformation. Solid-state transformations may be influenced by the resulting microsegregation pattern leading to development of a layered or banded microstructure. The below parameters are used for the ASTM1268 Banding Analysis.

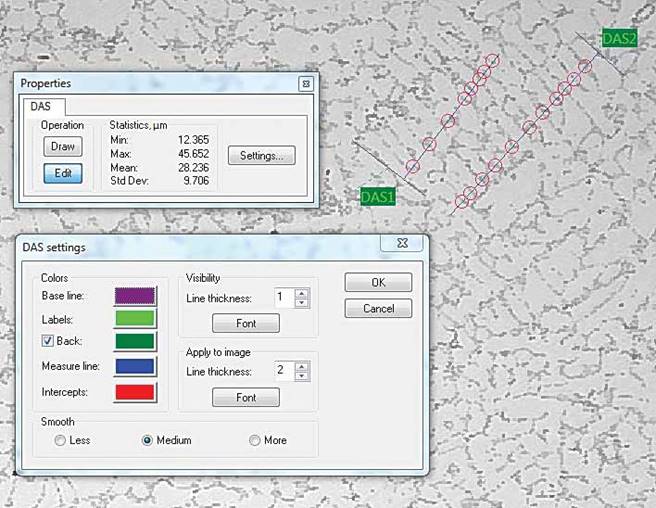

DAS (Dendrite Arm Spacing), ARP1947-2007/08

- This procedure is for determining the acceptability of the dendrite arm spacing (DAS) of D357-T6 aluminum alloy castings that have a specified tensile strength. Dendrite arm spacing (DAS) refers to the spacing between the secondary arms of the dendrite structure. Based on the ARP1947-2007 / 8 standard, a straight line is drawn perpendicularly to the growth direction of the secondary arms. Each space is then measured automatically. Average, Min, Max, and Standard Deviation measurement values are generated automatically.

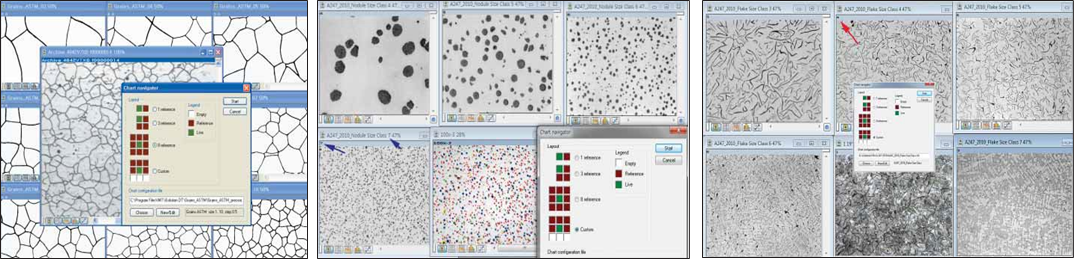

Chart Navigator

- The Chart Navigator permits direct comparison between either live or captured images with a series of reference images. The user-friendly interface allows you to quickly select the appropriate reference image which most closely matches the live or captured image. Both the live image and the reference image can be exported to MS Excel by a simple mouse click.

The Synchronize Zoom function maintains the magnification relationship between the reference image(s) and the live or captured image when using the image Zoom tool. Included reference images are: ASTM A247_2010 Distribution, ASTM A247_2010 Flake Size Class, ASTM A247_2010 Graphite Form, ASTM A247_2010 Nodule Size Class, ASTM A-247, Grain ASTM, Twin Grain ASTM, ISO TR 945-2_2011 Graphite Form, Sinter Cast CGI (Compacted Graphite Iron).

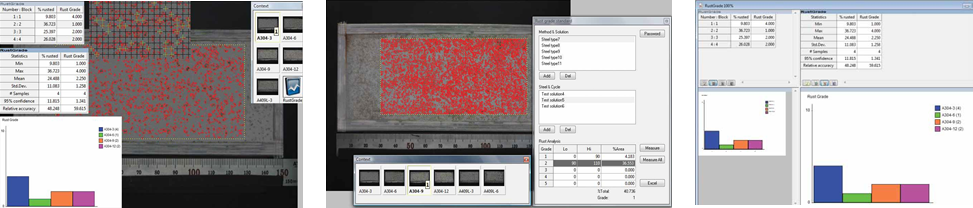

Rusting Degree Analysis (ASTM D 610-2008 and JIS H 8681-2:1999)

- This feature covers the evaluation of the degree of rusting on painted steel surfaces based on ASTM D610-2008. It provides a standardized means for quantifying the amount and distribution of visible surface rust. JIS H 8681-2: 1999 is for asseement of the corrosion resistance of anodic oxide coatings on aluminum and aluminum alloys based on JIS H 8681-2: 1999. The software also provides customizable methods and tables with which the user can create customized criteria. All user-created criteria can be password protected to prevent un-authorized changes.

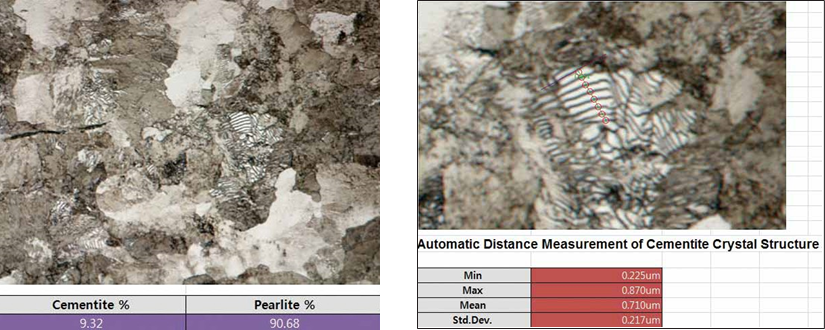

Cementite Crystal Structure Analysis

- Cementite volume Measurement :

Cementite and Pearlite Volume are measured to define the hardness and brittleness of materials

- Automatic Distance Measurement of Cementite Crystal Structure :

Each distance in Cementite Crystal Structure is measured automatically.

Layer Depth Measurement

- Average, Min, Max, Standard Dev. thickness of width are measured automatically by simply defining a box shape region of interest. Up to 999 scan lines can be specified.

|

|